sustainability

Print Green

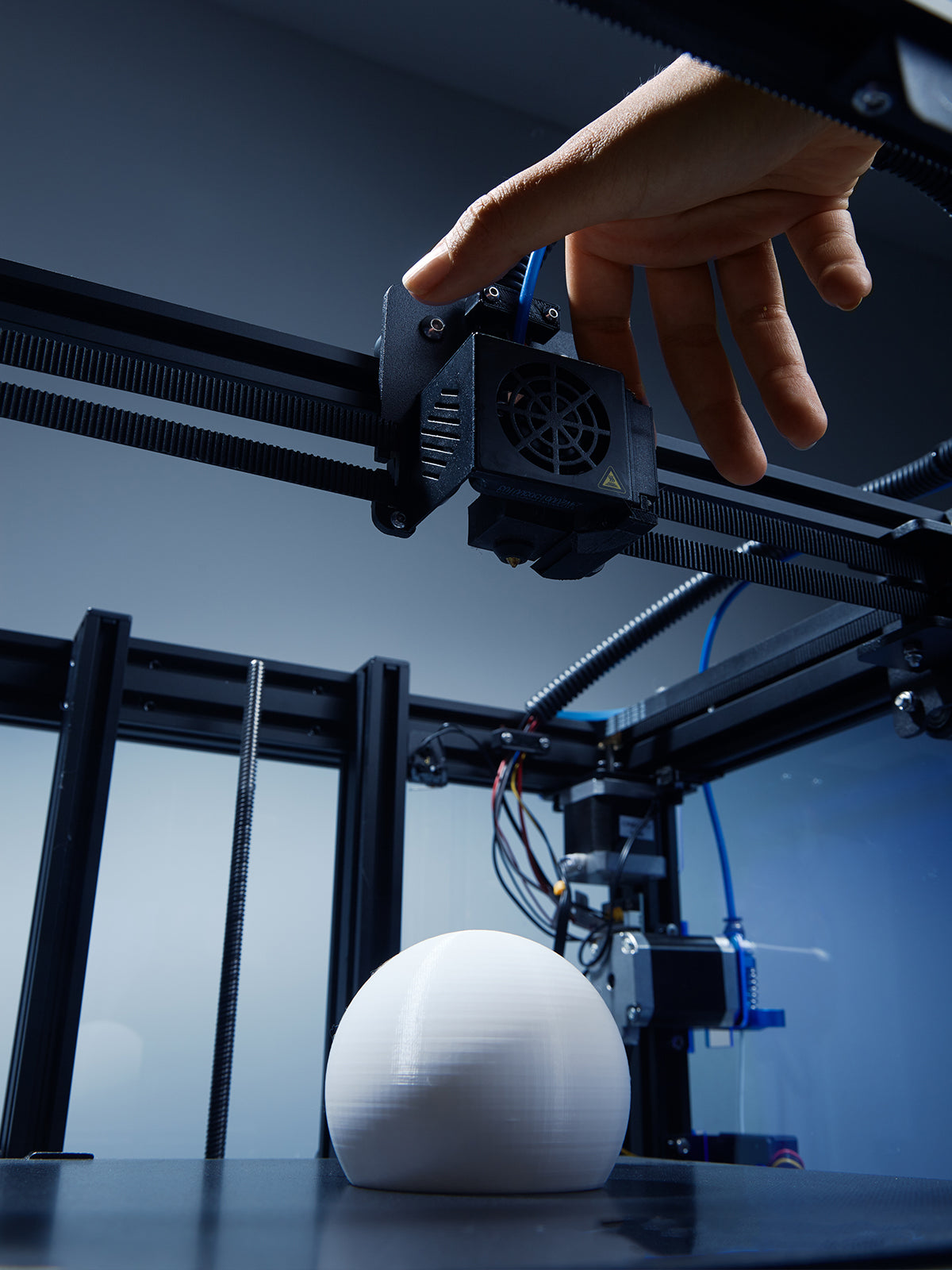

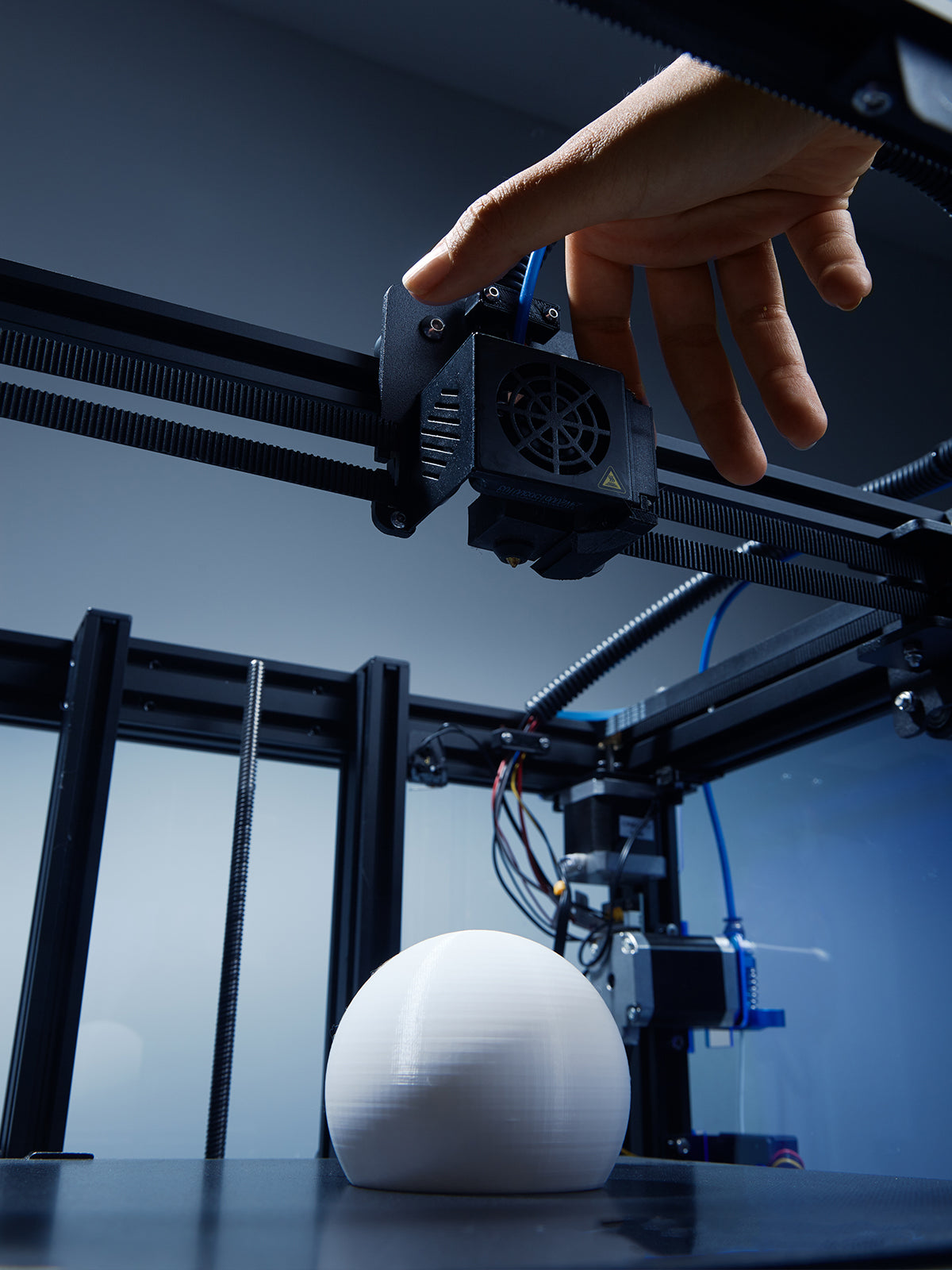

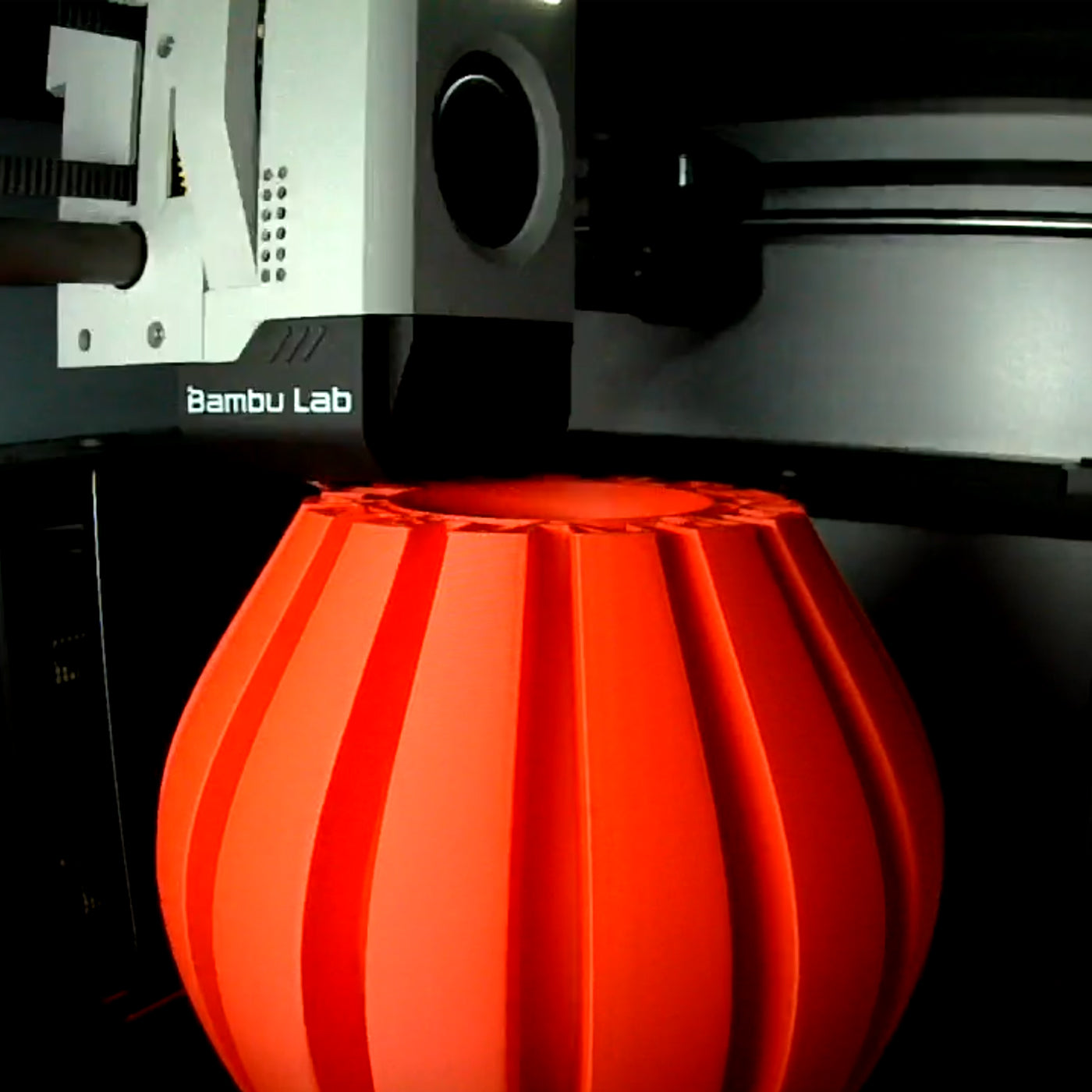

Innovative 3D printing technology for an environmentally friendly future.

We combine a passion for design with a commitment to the environment. Our 3D printed products are not only an expression of creativity and innovation, but also a commitment to sustainability. Made from corn starch, a bio-based and biodegradable material, we are setting new standards in environmentally friendly production.

We bring sustainable material into shape.

100%

biodegradable material

90%

lower carbon footprint

Our key to sustainability lies at the core of our products: 100% bio-based corn starch. This revolutionary material is not only renewable but also fully compostable, making it an environmentally friendly alternative to traditional plastics. By using corn starch, we reduce the use of fossil fuels, minimize the carbon footprint and support a circular economy where products can be returned to nature at the end of their life cycle.

In addition to choosing a sustainable material, we place great emphasis on an energy-efficient manufacturing process. Our 3D printing process makes it possible to manufacture products with minimal energy savings and almost no waste. Compared to traditional production methods, 3D printing can reduce energy consumption by up to 50%. This efficiency not only helps reduce our environmental footprint, but also paves the way for a more environmentally friendly future for the manufacturing industry.

Our key to sustainability lies at the core of our products: 100% bio-based corn starch. This revolutionary material is not only renewable but also fully compostable, making it an environmentally friendly alternative to traditional plastics. By using corn starch, we reduce the use of fossil fuels, minimize the carbon footprint and support a circular economy where products can be returned to nature at the end of their life cycle.

In addition to choosing a sustainable material, we place great emphasis on an energy-efficient manufacturing process. Our 3D printing process makes it possible to manufacture products with minimal energy savings and almost no waste. Compared to traditional production methods, 3D printing can reduce energy consumption by up to 50%. This efficiency not only helps reduce our environmental footprint, but also paves the way for a more environmentally friendly future for the manufacturing industry.

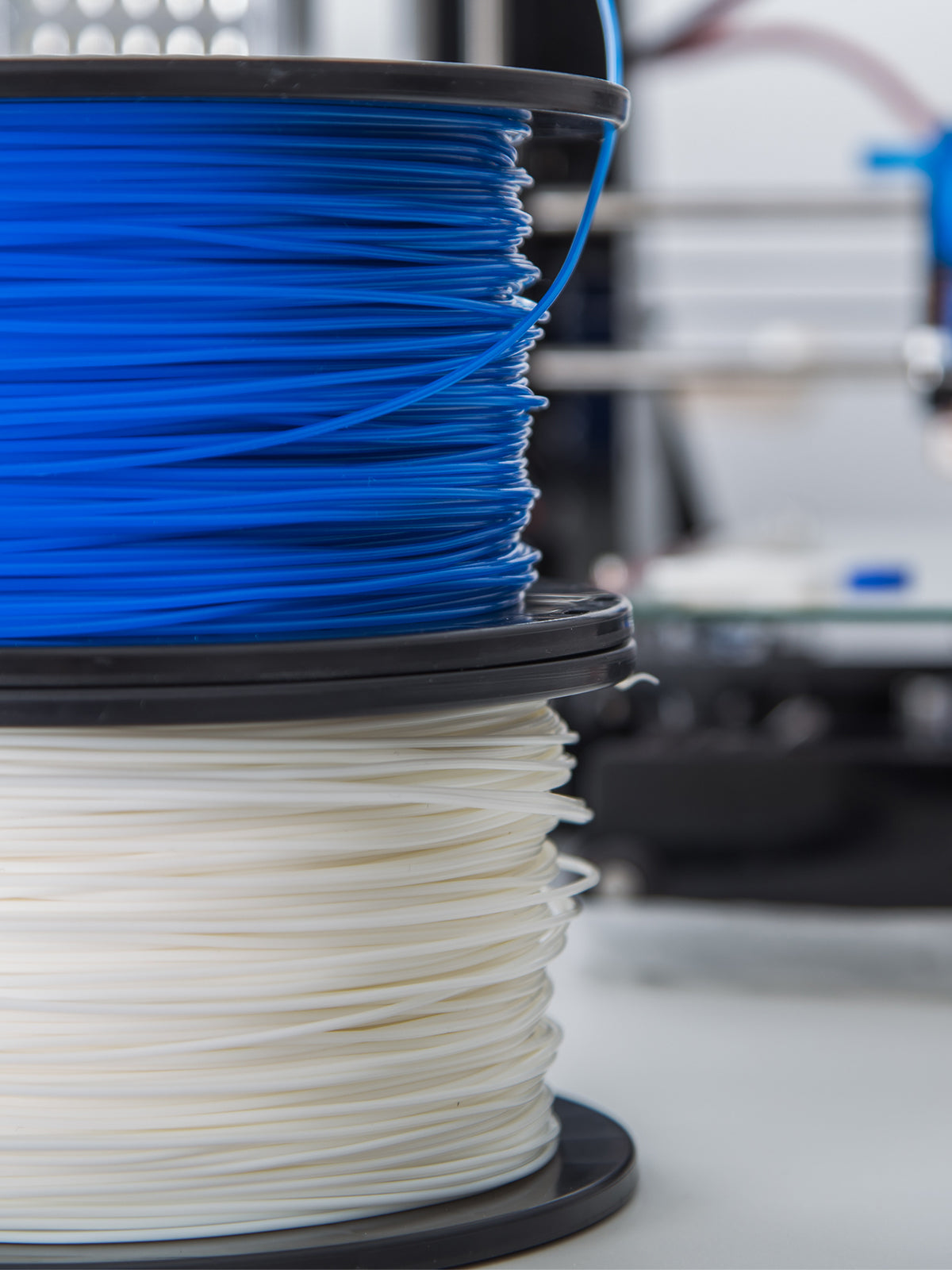

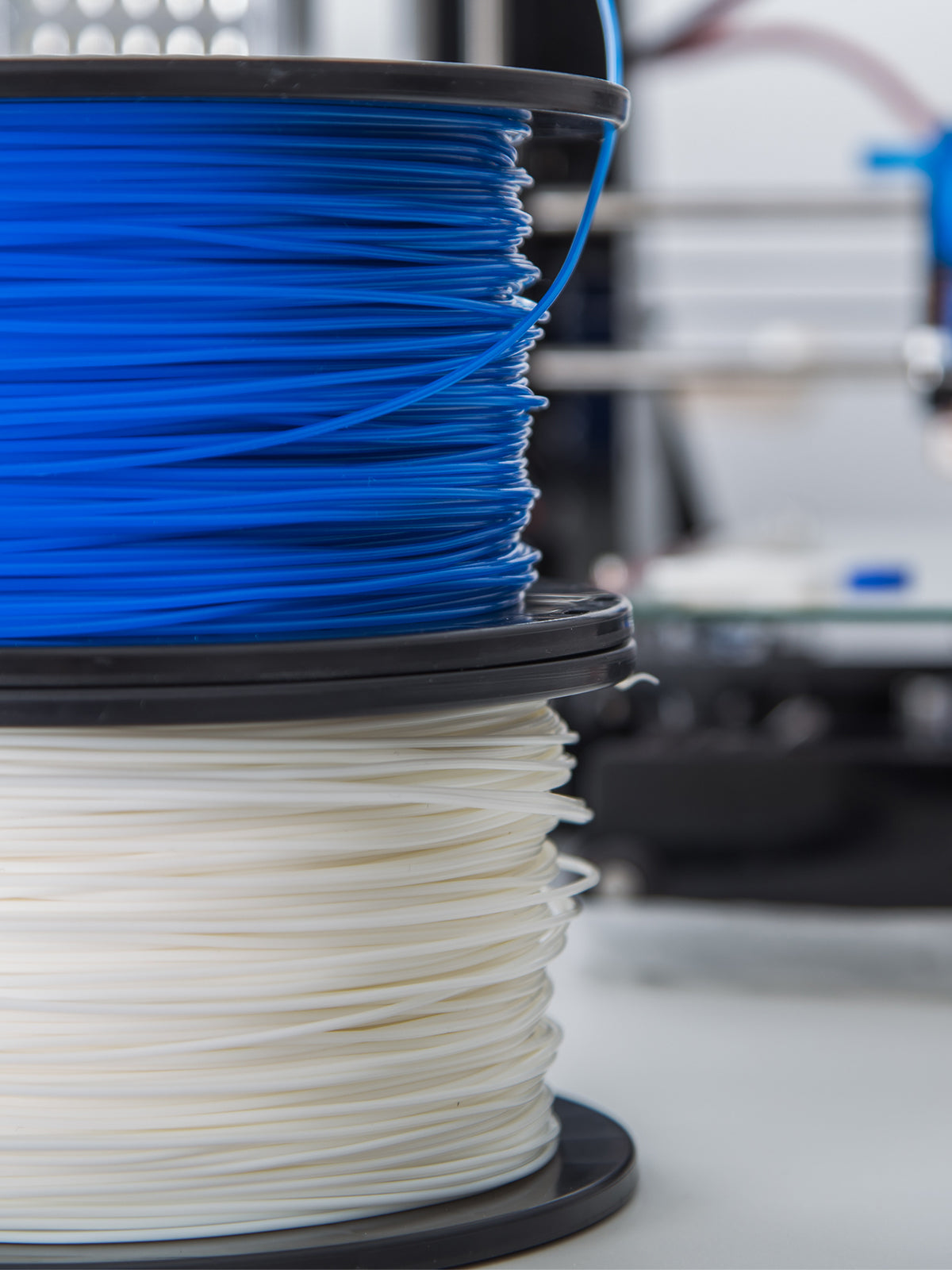

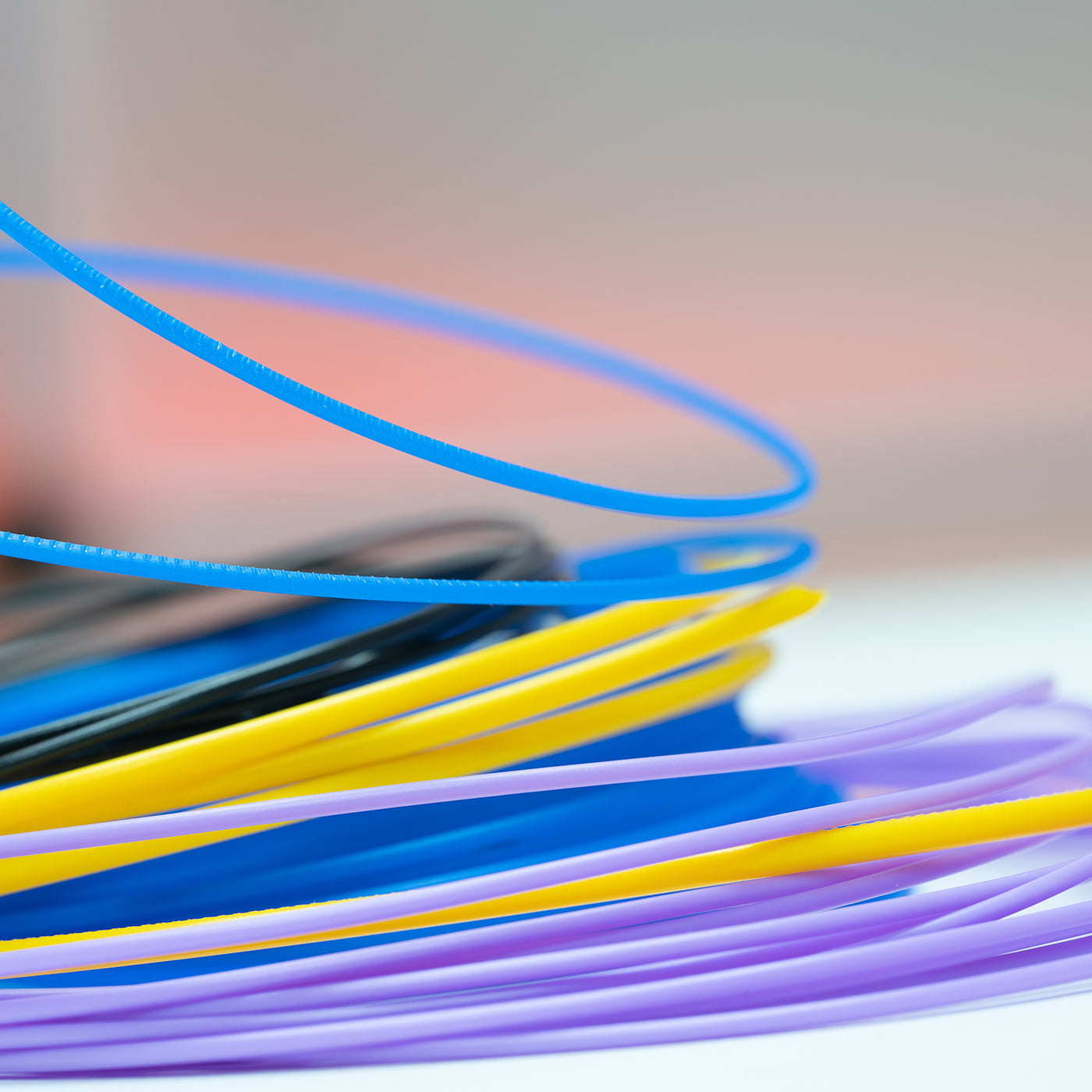

Our material

The PolyTerra™ PLA Filament

Progressiveness

The PolyTerra PLA filament combines ecological sustainability with outstanding print quality, reduces the plastic content and offers improved mechanical properties for versatile applications.

innovation

The filament is characterized by an innovative composition that contains less plastic and more organic minerals. This composition reduces the ecological footprint and increases the environmental friendliness of the material.

engagement

Every purchase of a PLA filament contributes to reforestation, as in cooperation with OneTreePlanted.org a tree is planted for every spool sold.

Production of Polyterra PLA material

Focus on sustainability

PolyTerra PLA is more than just a 3D printing material. It combines renewable resources with advanced technology to create a more environmentally friendly filament.

Our goal: Good for design, even better for the planet.

Our highlights